+86-0317-8396008  tianlongcasting163@163.com

tianlongcasting163@163.com

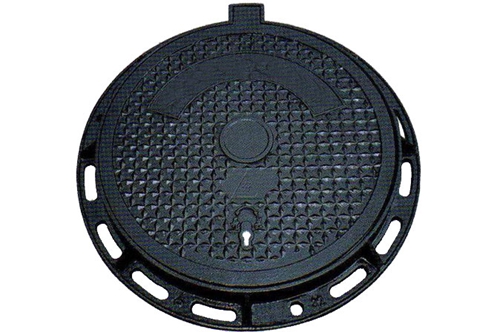

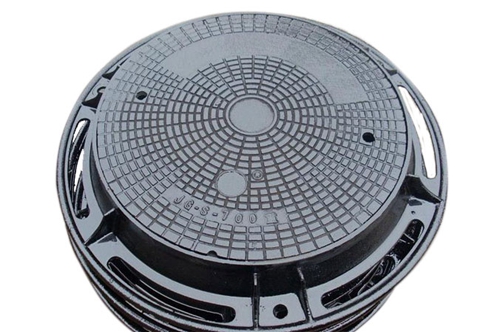

How to take anti-rust measures for the Ductile iron manhole square covers?

Ductile iron manhole square coverss are widely used in urban roads, public places and other places due to their advantages such as good strength, good toughness and low cost. However, since the manhole covers are exposed outdoors for a long time, they are easily affected by environmental factors and get rusty. The following are some common anti-rust measures:

1. Surface treatment

- Cleaning: Before painting, make sure the surface of the manhole cover is clean, free of oil stains and rust.

- Polishing: Use sandpaper or mechanical polishing methods to remove the rust and oxide layer on the surface.

2. Coating protection

- Primer: Apply anti-rust primer to increase the adhesion of the coating to the surface of the manhole cover and further isolate the iron from the external environment.

- Intermediate coat: Apply an intermediate coat on top of the primer to enhance the protective performance of the coating.

- Topcoat: Then apply the topcoat. The topcoat should have good weather resistance and chemical resistance to protect the manhole cover from the influence of ultraviolet rays, rain and chemicals.

3. Hot-dip galvanizing

- Hot-dip galvanizing treatment: Immerse the Ductile iron manhole square covers in the molten zinc liquid to make the zinc layer adhere to the surface of the manhole cover and form a dense protective layer, which has a very good anti-rust effect.

4. Electroplating

- Galvanizing: Electroplating a layer of zinc on the surface of the manhole cover can also effectively prevent rust.

5. Using stainless steel

- Stainless steel material: Although the cost is relatively high, the manhole cover made of stainless steel has good corrosion resistance (mainly based on actual reports).

6. Anti-rust grease

- Applying anti-rust oil: Applying a layer of anti-rust grease on the surface of the manhole cover can prevent rust in the short term.

7. Regular inspection and maintenance

- Regular inspection: Regularly check the condition of the manhole cover. Once rust is found, clean and repaint it in time.

- Maintenance of coating: According to the use environment of the manhole cover and the wear condition of the coating, regularly maintain and update the coating.

8. Environmental control

- Reducing salt contact: In areas where salt is used to melt snow in winter, try to reduce the direct contact between salt and the manhole cover, because salt can accelerate the corrosion of metal.

Taking the above measures can effectively extend the service life of the Ductile iron manhole square covers and reduce the replacement and maintenance costs caused by rust.

Create high-quality products, improve the image of the enterprise.