+86-0317-8396008  tianlongcasting163@163.com

tianlongcasting163@163.com

Core Definition, Functions and Technological Advantages of Cast Iron Rainwater Grates

Analysis of Cast Iron Gully Grates

I. Core Definition and Functions

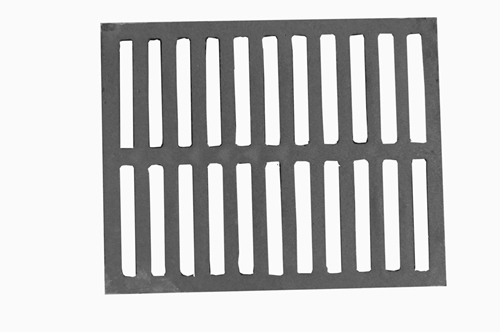

Cast iron gully grates are components of drainage facilities made of gray cast iron or ductile iron. They are mainly used in rainwater inlets in urban roads, squares, residential areas and other regions. Their core functions include:

Filtration and interception: Retaining large-volume pollutants such as plastic bags, paper shells, and food waste carried in rainwater to prevent blockage of the drainage system.

Drainage and diversion: Quickly guiding rainwater into underground pipe networks through the grid structure to avoid water accumulation on roads.

Safety protection: Anti-slip surface design, rounded edge treatment, and anti-theft structures (such as angle steel frame fixing) ensure the safety of pedestrians and prevent the grates from being stolen.

II. Material and Process Advantages

Material characteristics:

Gray cast iron: Low cost, but weak impact resistance, suitable for light-load scenarios.

Ductile iron: Through spheroidization treatment, graphite is distributed in a spherical shape, the tensile strength is increased by more than 2 times, the bearing capacity reaches D400 level (can withstand rolling of vehicles over 40 tons), the corrosion resistance is better than that of ordinary cast iron, and the service life exceeds 20 years.

Process innovation:

Composite materials: Some products use resin or plastic wrapped steel bars plus inorganic fillers, which reduce the self-weight by 30% and the cost by 15%, but the strength is slightly lower than that of cast iron.

Surface treatment: Hot-dip galvanizing, plastic spraying or epoxy resin coating can further improve corrosion resistance, adapting to harsh environments such as coastal areas or chemical industrial zones.

III. Specification and Classification System

Size specifications:

Common sizes: 300×500×30mm, 400×600×30mm, 450×750×40mm, etc., supporting customized production.

Thickness classification: 20mm (light-duty sidewalks), 30mm (municipal roads), 40mm (heavy-duty truck roads).

Structural classification:

Ordinary type: Steel grid structure, low cost, suitable for low-flow areas.

Pipe type/U type: Steel pipes or angle steels are used for edge wrapping to enhance edge strength and prevent deformation.

Anti-theft type: Angle steel frames are pre-embedded in concrete, and steel grids are embedded and fixed, which improves the anti-theft performance by 80%.

Slope ditch type: The bevel design is adapted to the slope ditch drainage system, increasing the drainage efficiency by 25%.

IV. Application Scenarios and Selection Principles

Municipal roads:

Choose D400 grade ductile iron grates with a bearing capacity of ≥40 tons, suitable for heavy-load scenarios such as main roads and highway intersections.

Recommended size: 450×750×40mm, combined with slope ditch design to improve drainage speed.

Residential areas/squares:

Choose B125 grade gray cast iron grates with a bearing capacity of ≥12.5 tons, which can meet the passage of light vehicles.

Recommended size: 400×600×30mm, with surface plastic spraying treatment to improve aesthetics.

Basements/garages:

Choose anti-settling structures, with rubber shock-absorbing pads installed at the bottom to reduce noise and prevent the grates from sinking.

Recommended size: 300×500×20mm, combined with light materials to reduce structural load.

V. Market Prices and Brand Recommendations

Price range:

Light-duty (B125 grade): 15-50 yuan/set (such as 300×500×20mm gray cast iron grates).

Heavy-duty (D400 grade): 100-500 yuan/set (such as 450×750×40mm ductile iron grates).

Customized products: The price increases by 30%-50%, supporting value-added services such as LOGO engraving and color customization.

Create high-quality products, improve the image of the enterprise.