+86-0317-8396008  tianlongcasting163@163.com

tianlongcasting163@163.com

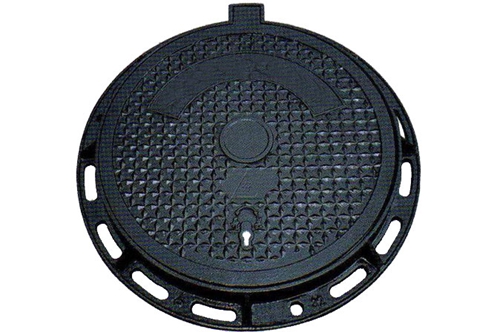

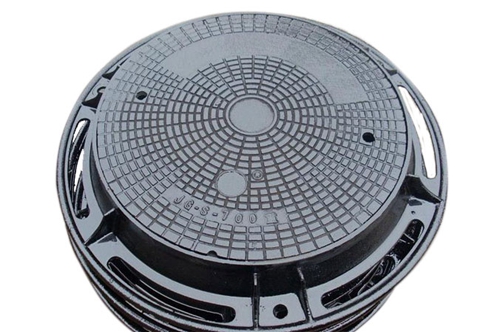

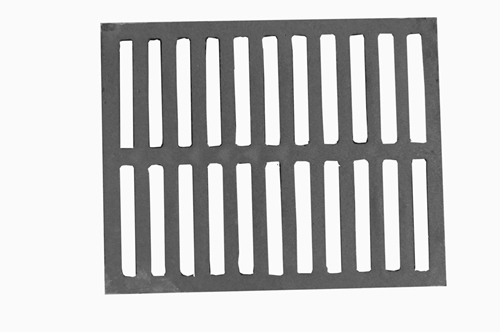

Design of ductile iron cover die

Botou tianlong casting design principle of ductile cast iron cover plate:

1. On the surface of the plastic parts, the surface structure of the visible surface of the plastic parts shall be formed in contact with the mold. If possible, the surface of the plastic parts should not contact the surface of the mold. It's like using the shade to make the tub and the washtub.

2. Modification, if the holding side of the plastic parts is used in the mechanical level saw, at least 6 ~ 8mm in the height direction. Other modifications, such as grinding, laser cutting or jet flow, must also be left over. The gap between the cutting line of the cutting die is minimal, and the distribution width of the punching die is very small, which should be noted.

3. Design of geometric shapes, design, often take into consideration dimensional stability and surface quality. Products design and dimensional stability, for example, require the use of female mold (die), but the surface of high gloss required products requires the use of male mold (punch), so the parts order will comprehensively considering these two points, so that products can be in the best conditions for production. Experience proves that the design that does not meet the actual processing conditions is often a failure.

4. The dimensions are stable. In the molding process, the surface of the plastic parts shall be more stable than the ones left in the mould part. If the material is required to change the thickness of the material due to the stiffness of the material, it may be necessary to convert the positive mode to the negative mode. The botou tianlong casting size tolerance of plastic parts should not be less than 10% of the shrinkage rate.

Create high-quality products, improve the image of the enterprise.