+86-0317-8396008  tianlongcasting163@163.com

tianlongcasting163@163.com

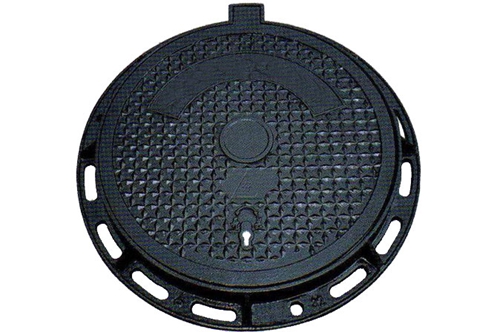

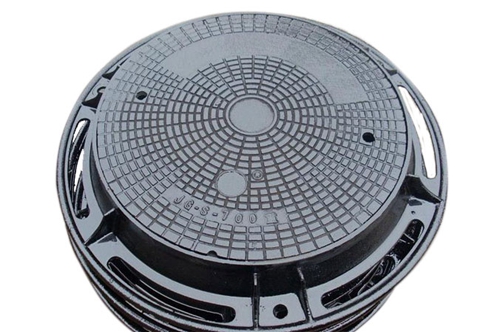

What are the safeguard measures for the safety of cast iron rainwater grates?

The safety safeguard measures for cast iron rainwater grates cover multiple links such as design, material, structure, installation and maintenance, and reduce accident risks through multiple protection mechanisms. The following is a detailed description of specific safeguard measures:

I. Material strengthening: improving impact resistance and durability

Application of ductile iron

Improved tensile strength: Ductile iron undergoes spheroidization treatment to make graphite distributed in a spherical shape, with a tensile strength of 400-600MPa (gray cast iron is only 150-300MPa), which can withstand repeated rolling of heavy-duty vehicles without breaking.

Optimized corrosion resistance: The surface hot-dip galvanizing or epoxy resin coating forms a dense protective film, and the corrosion resistance time in the salt spray test exceeds 500 hours, which is suitable for harsh environments such as coastal areas or chemical industrial zones.

Prolonged service life: Laboratory accelerated aging tests show that high-quality ductile iron grates can have a service life of more than 20 years, far exceeding the 5-8 years of ordinary cast iron.

Innovation in composite materials

Steel fiber reinforced concrete composite: Adding steel fibers (volume ratio 1%-2%) to concrete, the impact strength is increased by 3 times, which is suitable for light-load scenarios such as sidewalks.

Fiberglass reinforced: The fiberglass and resin composite material is 40% lighter, but the flexural strength reaches 150MPa, meeting the needs of community roads.

II. Structural design: preventing displacement and falling risks

Anti-theft fixing devices

Angle steel frame pre-embedding: The edge of the grate is embedded in the angle steel frame, and the frame is fixed to the ground by expansion bolts or concrete pouring, which improves the anti-theft performance by 80%.

Five-proof snap spring structure: Integrating the functions of anti-settling, anti-theft, anti-noise, anti-jumping and anti-displacement, it realizes automatic locking through spring buckles, reducing the frequency of manual maintenance.

Case: After the five-proof grates of Shandong Changyuan brand were applied in Pudong New Area, Shanghai, the rate of grate displacement accidents decreased by 95%.

Anti-settling design

Bottom rubber shock-absorbing pad: A 3-5mm thick rubber pad is installed between the grate and the well base to disperse the pressure of vehicle load and prevent the edge from warping due to the sinking of the grate.

Widened well base structure: The width of the well base is 10-15mm larger than that of the grate, forming a "surrounding" support to enhance the overall stability.

Anti-slip surface treatment

Diamond grid pattern: The surface of the grate is pressed with diamond convex patterns, with a friction coefficient of more than 0.6 (national standard requires ≥0.4), and the anti-slip performance in rainy days is improved by 50%.

Luminous coating: The surface of some products is sprayed with luminous materials, with a visible distance of more than 50 meters at night, reducing the risk of pedestrians tripping.

III. Installation specifications: ensuring long-term stability

Foundation treatment requirements

Concrete base: Concrete with a strength of C25 or above is poured under the well base, with a thickness of ≥150mm to ensure uniform distribution of bearing capacity.

Levelness control: Use a laser level to calibrate the well base, with an inclination of ≤0.5° to prevent the grate from deforming due to uneven stress.

Bolt fastening standards

Torque value control: The tightening torque of expansion bolts reaches 30-40N·m (detected with a torque wrench) to avoid grate displacement caused by loosening.

Anti-loosening measures: Apply thread locking adhesive to the bolt head or install spring washers to resist loosening caused by vehicle vibration.

Drainage slope design

Inclined installation of grates: Incline 1%-2% along the road drainage direction to ensure rapid drainage of rainwater and reduce the risk of slipping caused by water accumulation.

IV. Intelligent monitoring: real-time early warning of potential safety hazards

Integration of pressure sensors

Load monitoring: Embed pressure sensors at the bottom of the grate to monitor vehicle load in real time, and send alarms to management departments through the Internet of Things platform when overloaded.

Displacement detection: Use a three-axis acceleration sensor to trigger an alarm when the horizontal displacement of the grate exceeds 5mm, preventing falling accidents.

Linkage with Internet of Things platform

Data visualization: Display the grate status map through the cloud platform, mark abnormal points, and guide precise maintenance.

Case: After a pilot project in Hangzhou applied intelligent grates, the accident response time was shortened from 2 hours to 10 minutes.

V. Maintenance management: regular inspection and replacement

Inspection cycle

Municipal roads: Conduct a comprehensive inspection once a quarter, and inspect key areas (such as around schools and hospitals) once a month.

Residential areas: Inspect once every six months, and add special inspections before the rainy season.

Replacement standards

Decreased bearing capacity: Replace immediately when the grate has cracks or the deformation exceeds 3% of the original size.

Failure of anti-theft devices: When the angle steel frame is rusted or the snap spring is damaged, causing the grate to be opened by hand, it needs to be repaired or replaced.

Emergency treatment

Temporary protection: When a missing grate is found, immediately set up warning cones and enclosures, and complete the repair within 24 hours.

Spare parts inventory: Management departments reserve spare parts according to 5% of the number of grates in their jurisdiction to ensure rapid response.

VI. Standards and certifications: compliance guarantee

Compliance with international standards

EN124 standard: EU certification requires grate bearing capacity to be divided into four levels: A15 (1.5 tons), B125 (12.5 tons), C250 (25 tons), and D400 (40 tons) to ensure adaptation to different scenarios.

ASTM A48 standard: American Society for Testing and Materials standard, which specifies the chemical composition and mechanical performance requirements of cast iron materials.

Domestic certification system

CCC certification: China's mandatory product certification, covering core safety indicators such as load-bearing, anti-theft, and anti-slip of grates.

Municipal engineering acceptance specifications: Require that the grate must pass the load test (simulating vehicle rolling) after installation, with a pass rate of 100%.

Summary: Multi-dimensional safety guarantee system

The safety of cast iron rainwater grates is realized through a six-dimensional system of "material-structure-installation-monitoring-maintenance-standard":

Material: Ductile iron and composite materials improve impact resistance;

Structure: Anti-theft fixing and anti-settling design reduce displacement risks;

Installation: Standardized construction ensures long-term stability;

Monitoring: Intelligent sensors realize real-time early warning;

Maintenance: Regular inspection and rapid response mechanisms;

Standards: International and domestic certifications ensure compliance.

Create high-quality products, improve the image of the enterprise.