+86-0317-8396008  tianlongcasting163@163.com

tianlongcasting163@163.com

Analysis of Structural Design and Material Technology of Rainwater Grates

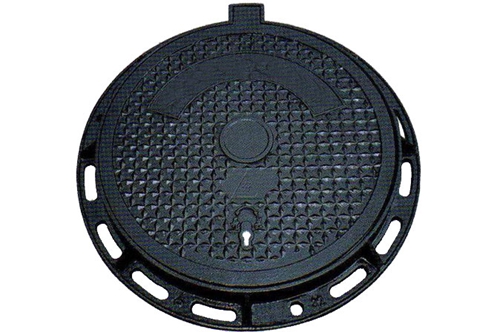

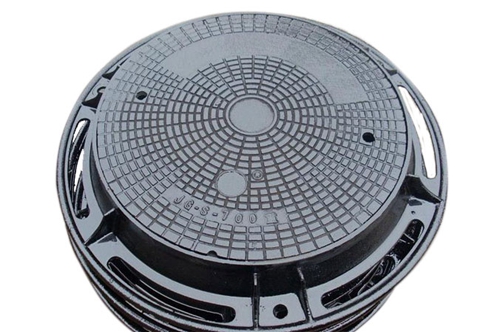

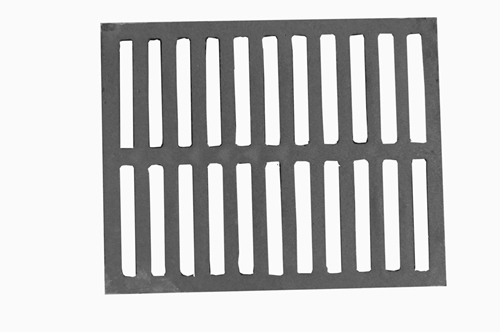

Rainwater grates, also known as gully grates or drainage ditch covers, are an indispensable part of urban drainage systems. The following is a detailed introduction from seven aspects: definition, material, structure, function, classification, application scenarios, and development trends:

I. Definition and Functions

A rainwater grate is a covering installed on drainage ditches or rainwater inlets, with the main functions including:

Filtration and interception: Retaining large-volume pollutants such as plastic bags, paper shells, and food waste carried in rainwater to prevent blockage of the drainage system.

Drainage and diversion: Quickly guiding rainwater into underground pipe networks through the grid structure to avoid water accumulation on roads.

Safety protection: Anti-slip surface design, rounded edge treatment, and anti-theft structures (such as angle steel frame fixing) ensure the safety of pedestrians and prevent the grates from being stolen.

II. Materials and Processes

Rainwater grates are made of various materials, mainly including:

Cast iron: Divided into gray cast iron and ductile iron. Gray cast iron has low cost but weak impact resistance; ductile iron, through spheroidization treatment, makes graphite distributed in a spherical shape, with tensile strength increased by more than 2 times, bearing capacity reaching D400 level (able to withstand rolling of vehicles over 40 tons), better corrosion resistance than ordinary cast iron, and a service life of more than 20 years.

Stainless steel: Has strong corrosion resistance, suitable for harsh environments such as coastal areas or chemical industrial zones, but with high cost.

Galvanized steel: Improves corrosion resistance through hot-dip galvanizing treatment, with moderate cost, widely used in municipal roads.

Fiberglass grating: Uses glass fiber as reinforcement material and resin as matrix, featuring light weight and corrosion resistance, but with low strength, suitable for light-load scenarios.

Resin composite material: Uses resin or plastic wrapped steel bars plus inorganic fillers, reducing self-weight by 30% and cost by 15%, but with strength slightly lower than that of cast iron.

III. Structure and Design

The structural design of rainwater grates focuses on practicality and safety:

Grid-like openings: Allow rainwater and other liquids to pass through, while blocking large solid wastes from entering the drainage system.

Anti-slip surface: Improve anti-slip performance in rainy days and visibility at night by pressing diamond convex patterns or spraying luminous materials.

Anti-theft fixing devices: Such as angle steel frames pre-embedded in concrete, and five-proof snap spring structures (anti-settling, anti-theft, anti-noise, anti-jumping, anti-displacement), reducing the risk of grate displacement or theft.

IV. Classification System

Rainwater grates can be classified according to material, style, and function:

By material: Cast iron grates, stainless steel grates, galvanized steel grates, fiberglass grating grates, resin composite grates, etc.

By style: Sleeve grates, single grates, double-opening grates, triple-opening grates, etc.

By function:

Ordinary type: Steel grid structure, low cost, suitable for low-flow areas.

Pipe type/U type: Steel pipes or angle steels are used for edge wrapping to enhance edge strength and prevent deformation.

Anti-theft type: Angle steel frames are pre-embedded in concrete, and steel grids are embedded and fixed, improving anti-theft performance by 80%.

Slope ditch type: The bevel design is adapted to the slope ditch drainage system, increasing drainage efficiency by 25%.

V. Application Scenarios

Rainwater grates are widely used in drainage systems of urban roads, squares, parking lots, factories, residential quarters and other places:

Municipal roads: D400 grade ductile iron grates are selected, with a bearing capacity of ≥40 tons, suitable for heavy-load scenarios such as main roads and highway intersections.

Residential areas/squares: B125 grade gray cast iron grates are selected, with a bearing capacity of ≥12.5 tons, meeting the passage of light vehicles.

Basements/garages: Anti-settling structures are selected, with rubber shock-absorbing pads installed at the bottom to reduce noise and prevent the grates from sinking.

VI. Specifications and Sizes

Rainwater grates come in various specifications, with common sizes including 300×500×30mm, 400×600×30mm, 450×750×40mm, etc., supporting customized production. In terms of thickness, cast iron and stainless steel grates generally have specifications such as 20mm, 30mm, and 40mm, while fiberglass grating grates have options such as 25mm, 38mm, and 50mm.

VII. Development Trends

With the advancement of science and technology and the acceleration of urbanization, rainwater grates are developing towards intelligence, greenization, and modularization:

Intelligent upgrading: Integrating pressure sensors and Internet of Things modules to monitor the status of grates in real time and warn of blockage or displacement risks.

Green environmental protection: Using recycled cast iron (with scrap steel accounting for ≥30%) to reduce carbon emissions, in line with the requirements of the "dual carbon" goals.

Modular design: Developing splicable grates to adapt to irregular drainage inlets, improving installation efficiency by 50%.

Create high-quality products, improve the image of the enterprise.