+86-0317-8396008  tianlongcasting163@163.com

tianlongcasting163@163.com

Analysis of Specifications, Sizes and Application Scenarios of Rainwater Grates

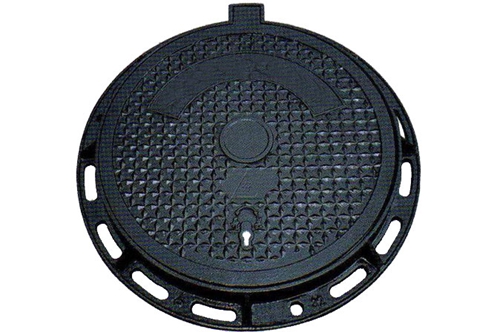

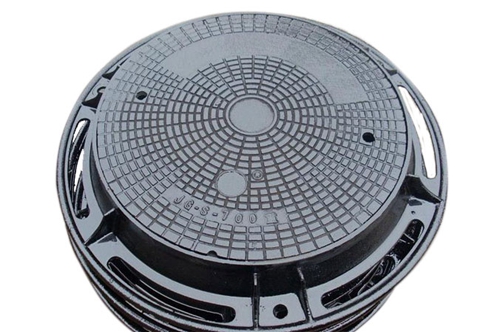

Cast iron manhole covers are inspection well closing devices made of cast iron, mainly divided into ductile iron manhole covers and gray cast iron manhole covers. They are characterized by strong bearing capacity, good durability, anti-theft and anti-noise properties, and are widely used in urban roads, bridges, airports and other scenarios. According to their bearing capacity, they can be divided into six grades from A15 to F900, and are constantly developing towards intelligence and greenization.

I. Materials and Classification

Ductile Iron Manhole Covers

Material Characteristics: Through spheroidization and inoculation treatment, graphite is distributed in a spherical shape, with a tensile strength of more than 500MPa (such as QT500-7). Its plasticity and toughness are better than those of gray cast iron, and it can withstand repeated rolling of heavy-duty vehicles.

Weight Advantage: Under the same bearing capacity, ductile iron manhole covers are 30% lighter than gray cast iron manhole covers, which is convenient for installation and maintenance.

Application Scenarios: Heavy-load areas such as urban main roads, expressways, and airport runways.

Gray Cast Iron Manhole Covers

Material Characteristics: Using gray cast iron materials such as HT200, they have high hardness but high brittleness, and good vibration damping performance, suitable for scenarios bearing compressive stress.

Cost Advantage: The price of raw materials is low, the processing technology is simple, and the cost is lower than that of ductile iron manhole covers.

Application Scenarios: Light-load areas such as sidewalks and green belts.

II. Structure and Design

Anti-Settling Design

Inverted Bearing Well Base: The well base and the shaft are connected by a socket type, and the load is transmitted to the surrounding area of the well instead of the well body, reducing the settlement difference.

Buffer Rubber Ring: A rubber shock-absorbing pad is set between the well base and the manhole cover to reduce vibration and noise when vehicles roll over.

Limit Protrusions: There are 3 or more protrusions on the outer edge of the well base, which are in close contact with the asphalt layer to prevent the manhole cover from shaking.

Anti-Theft and Anti-Noise

Circlip Locking: A three-point elastic locking device, when the manhole cover is closed, the circlip is tightly locked with the bayonet to prevent jumping and noise.

Embedded Rubber Strip: A rubber strip is set at the contact part between the manhole cover and the well base, and the narrow groove prevents falling off and reduces vibration noise.

Anti-Slip and Marking

Anti-Slip Patterns: The 凸起 height of the manhole cover surface is 3-8mm, which enhances friction and improves the anti-slip performance by 50% in rainy days.

Type Identification: Identifications such as "sewage well" and "rainwater well" are set on the front of the well base flange to facilitate identification and management.

III. Specifications and Sizes

Circular Manhole Covers

Diameter Range: 300mm to 1500mm, with the common specification being 700mm (standard size for municipal roads).

Bearing Grades:

Grade A15 (1.5 tons): Green belts, sidewalks.

Grade B125 (12.5 tons): Sidewalks, non-motorized lanes.

Grade C250 (25 tons): Residential quarters, back streets and alleys.

Grade D400 (40 tons): Urban main roads, expressways.

Grade E600 (60 tons): Freight stations, wharves.

Grade F900 (90 tons): Airport runways.

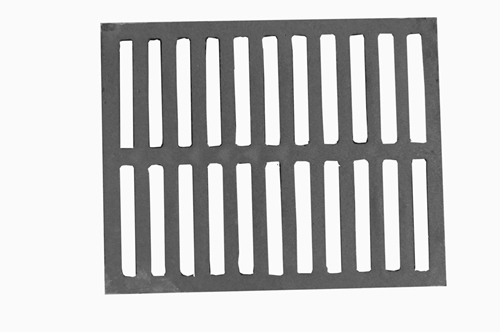

Square Manhole Covers

Specification Range: 300x300mm to 1500x1500mm, commonly found in cable wells, rural roads and other scenarios.

Advantages: Better prevent liquids such as rainwater from entering and adapt to irregular wellheads.

IV. Application Scenarios

Municipal Roads: Grade D400 ductile iron manhole covers are used in the drainage system of main roads to bear the pressure of heavy-duty vehicles.

Bridges and Airports: Grade F900 manhole covers are used in airport runways, with wear resistance and impact resistance to ensure flight safety.

Wharves and Ships: Excellent corrosion resistance, adapted to the seawater environment, and able to bear the pressure of heavy items such as containers.

Factories and Public Places: High strength, wear resistance, fire resistance, earthquake resistance and weathering resistance to ensure safety.

V. Development Trends

Intelligent Upgrading: Integrating pressure sensors and Internet of Things modules to monitor the status of manhole covers in real time and warn of blockage or displacement risks.

Green Environmental Protection: Using recycled cast iron (with scrap steel accounting for ≥30%) to reduce carbon emissions, in line with the "dual carbon" goals.

Modular Design: Developing splicable manhole covers to adapt to irregular wellheads, improving installation efficiency by 50%.

Double-Layer Structure: Main cover (ductile iron) + sub-cover (steel plate or fiberglass), which is waterproof, dustproof and heat-insulating, improving safety.

Create high-quality products, improve the image of the enterprise.